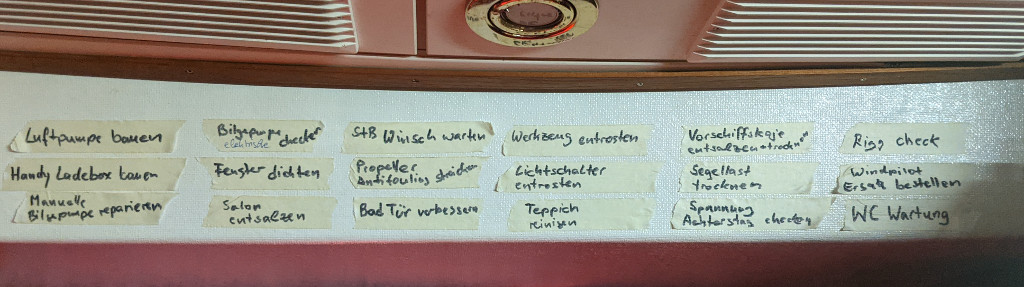

Nach ein paar Tagen Entspannung haben wir die anstrengenden Tätigkeiten aufgenommen. Wir beseitigen die Schäden, die die Überfahrt von Kuba nach Aruba hinterlassen hat. Wir beseitigen die Ursachen für diese Schäden. Und wir beseitigen neue Schäden, die nach der Überfahrt entstanden sind. Und uralte Schäden, die schon vorhanden waren, bevor wir in den Niederlanden im Sommer 2019 gestartet sind. Dabei machen wir Entdeckungen, die wir lieber nicht gemacht hätten. Wenn man als Landratte keine Ahnung hat, sollte man sich die Ahnung irgendwo besorgen oder man bezahlt hinterher mit Dollarnoten und Schweiß.

Vor ein paar Jahren waren wir mit Sissi in Schottland. Dabei haben wir festgestellt, dass nach hartem Segeln gegen den Wind ein paar Tropfen Wasser in der Vorschiffskabine sind. Die Ursache haben wir nie gefunden, es hat sich auch nicht wiederholt. Nahe Roscoff, an dem Tag als uns das Großsegel gerissen ist, hatten wir ein wenig Wasser im Salon. Sofort waren die Lüfter unter Verdacht, denn es ist ordentlich Wasser über das Deck geflossen. Warum mussten wir Esel auch gegen neun Windstärken ansegeln? Die Lüfter können jetzt wohl von ihrer Mütze befreien, ich spreche sie frei von jedweder Verantwortung für den Wasserschaden.

Auf der langen Überfahrt über den Atlantik beklagte sich über gelegentliche Feuchtigkeit in der Vorschiffskoje. Langsam bildete sich ein Verdacht auf eine Undichtigkeit des Ankerkastens. Die Feuchtigkeit ging, den Ankerkasten haben wir in Varadero geprüft, als Sissi auf dem Trockenen stand. Er sieht super aus. Die Feuchtigkeit geriet wieder in Vergessenheit, wir hatten andere Probleme zu lösen. Wir haben das Problem ausschließlich in der Vorschiffskoje verortet.

Nach dem Abnehmen der ersten Luke war mir klar, wo die ganze Feuchtigkeit herkommt. Vom Dichtungsband war nicht mehr viel übrig, die Schraublöcher von Salztürmchen überkrustet. Meine Landratten-Lebenserfahrung sieht Fenster als einigermaßen wartungsfreie Öffnungen in der Wand, durch die man seine Wohnung lüften kann. Böse.

Wie dichtet man diese Luken eigentlich vernünftig ab? Sicher nicht dadurch, dass man den Rahmen mit Sikaflex wieder neu einklebt. Außerdem haben die hiesigen Baumärkte das salzwassertaugliche Sika gar nicht im Angebot. Eine Fahrt zu Budget Marine später kommt Jens mit ein paar Rollen Dichtungsband zurück. Sehr gut, das Zeug ist auf Aruba zu kaufen.

Nun werden die Luken nacheinander abgenommen. Überall sehen wir, dass um die Schraublöcher Salzverkrustungen entstanden sind. Die alten Dichtungsbänder waren schon sehr alt. Sehr sehr alt. Immerhin habe ich Sissi schon seit 2017. Und da müssen die Bänder schon alt gewesen sein.

Mechanisch und chemisch werden die Fensterrahmen gereinigt und von Salz befreit. Auch das Boot wird gereinigt. Wo die neuen Gummis später dicht halten sollen darf kein Dreck oder Staub mehr sein. Dann wird der Rahmen beklebt.

Dann kommen die Luken wieder an Ort und Stelle. Leider tut sich an dieser Stelle einer der nächsten Abgründe auf. Durch die viele eingedrungene Feuchtigkeit und die Schiffsbewegungen drehen einige der Schrauben durch. Einige mehr, andere weniger. Insbesondere die Schrauben, mit denen die Scharniere der Luken befestigt sind, haben sehr leiden müssen.

Wir holen uns Rat bei einem Schreiner in Frankfurt. Wie kann man diese Löcher im Holz wieder kleiner bekommen, damit die Schrauben wieder halten? Zuerst rät er uns zu einer Lösung, auf die wir auch schon gekommen sind. Größere Schrauben nehmen. Das bedeutet natürlich wieder eine Fahrt in den Baumarkt.

Die größten Schrauben drehen in den größten Löchern durch? Dann müssen die Löcher zugeleimt werden. Haben wir Leim? Nein, natürlich nicht. Auch das bedeutet wieder eine Fahrt in den Baumarkt.

Eine Fahrt in den Baumarkt dauert mindestens eineinhalb Stunden, manchmal auch länger. Das hängt davon ab, wie lange man auf den Bus warten muss. Jetzt haben wir alles an Bord, die Fenster sind festgeschraubt und wir haben noch Ersatz für die Zukunft. Gerade überlegen wir, ob wir nicht die Baustelle mit den Seitenfenstern aufmachen sollen. Die Seitenfenster können auch heikel sein. Bisher war aber nur das neben Jens’ Koje undicht. Das bearbeiten wir auf jeden Fall.

Nachtrag:

Wenn man eine Arbeit das erste Mal in seinem Leben tut, kommt nicht immer gleich ein perfektes Ergebnis raus. Wir haben lernen müssen, dass man mit dem Vinylband besser nicht zu kleinteilig puzzelt.

Links oben im Ausschnitt sieht man, wie wir die Ecken zuerst beklebt haben. Wasser konnte zwischen den einzelnen Stücken hindurch, wie sich beim Wasserschlauch-Dichtigkeitstest ergeben hat – von innen viel zu schön an den Wassertropfen zu sehen, die wieder ihren Weg in den Salon fanden. Rechts oben im Ausschnitt die neue Lösung, die kein Wasser mehr nach innen lässt.

Moin , wo habe ich mal gelesen, dass Langfahrt bedeutet, sich von Hafen zu Hafen zu reparieren? 🙂 Eigentlich sollte man das Dichtband völlig ohne Zerstückelungen um die Kurven kriegen können. Die Salzverkrustungen halte ich übrigens für Korrosion, wie sie entsteht, wenn man Edelstahl (Schrauben) mit Aluminium (Rahmen) in Kontakt bringt. Um das zu verhindern, kann man die Schrauben vorher mit TIKAL TEF-Gel einschmieren. Gruß Klaus

Oder Monel Schrauben nehmen – die hat aber leider nicht jeder Baumarkt.